Service

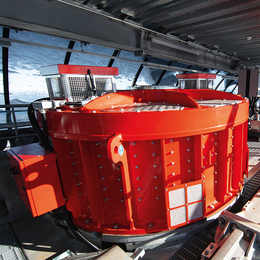

- Tele-assistance

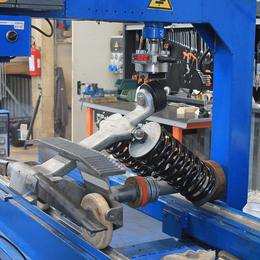

- Grip revision

- Services, contacts, hotline

- Repairs

- Training, education and courses at LEITNER

- Maintenance catalog